Gas turbine test lab

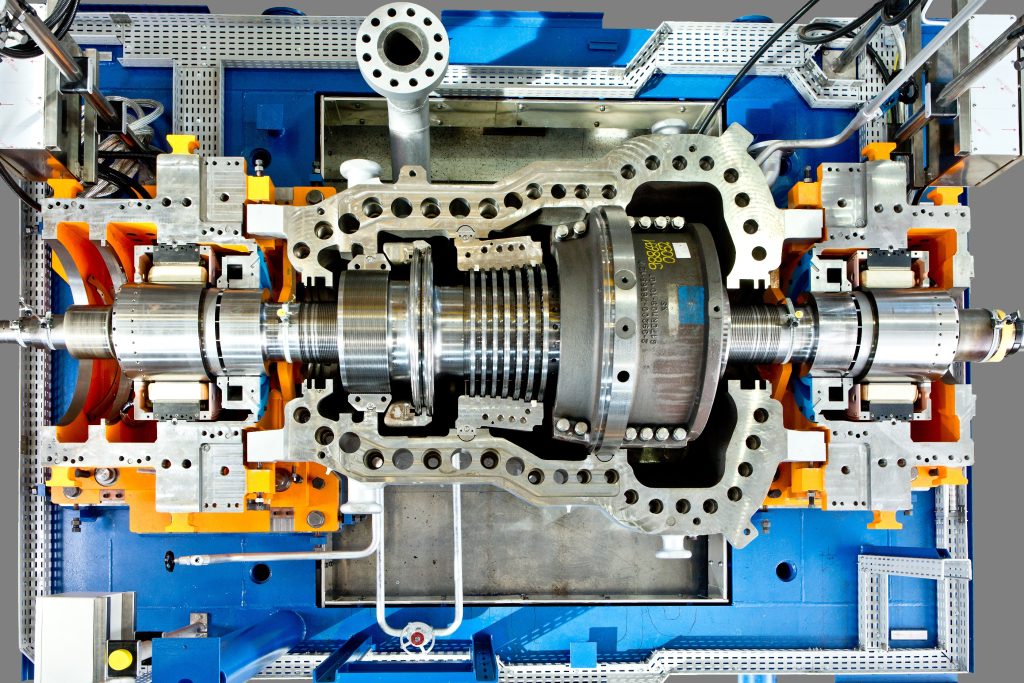

General Schematic of a Typical Gas Turbine Test Rig

Table of contents

Gas turbine test lab

Introduction

Gas turbine test rigs are used to obtain precise performance data under a wide range of operating conditions. The primary goals are to evaluate performance, safety, efficiency, and optimization of gas turbine engines. The following provides a comprehensive overview of all related aspects.

Importance and Necessity

Performance Improvement

Accurate testing enables efficiency gains and fuel consumption reduction.

Safety Assurance

Early identification and elimination of weak points significantly enhance system safety.

Dynamic Behavior Analysis

Examination of engine response to variations in pressure, temperature, and flow rate.

Standards Compliance

Verification that the engine meets international standards such as ISO and ASME.

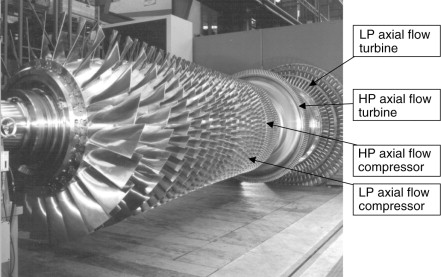

Key Components of a Gas Turbine Test Rig

Data Acquisition System

High-precision sensors and electronics for measuring temperature, pressure, vibration, airflow, and other parameters.

Air and Fuel Supply System

Designed to simulate real inlet conditions by precisely controlling air pressure, temperature, and fuel flow.

Control System

Central control unit for process management, monitoring, and emergency shutdown capabilities.

Engine/Turbine Under Test

This is the heart of the test rig, where performance data is collected.

Critical Parameters Measured

Compressor Pressure Ratio (CPR)

Ratio of compressor discharge pressure to inlet pressure.

Thermal Efficiency

Measure of how effectively thermal energy is converted to mechanical work.

Specific Fuel Consumption (SFC)

Fuel consumed per unit of thrust/power produced (g/kN·s or kg/kWh).

Temperature and Pressure at Key Stations

Including Exhaust Gas Temperature (EGT), turbine inlet temperature (TIT), and static pressures throughout the engine.

General process in gas turbine test lab

Initial Preparation

Equipment installation, sensor calibration.

Engine health checks.

Test Execution

Engine run at idle, part-load, and full-load conditions while varying parameters.

Measurement of key parameters such as thrust, temperature, pressure and fuel consumption.

Data Collection and Analysis

Real-time recording followed by post-processing to identify trends and anomalies.

Safety and Fault Inspection

Detection of excessive vibration, overheating, oil leaks, or surge/stall events.

Final Report Generation

Comprehensive documentation including performance curves, tables, and recommendations.

Challenges and Considerations

High Accuracy Requirements: Need for extremely precise instrumentation to ensure reliable data.

Operational Costs: Substantial expenses for design, construction, maintenance, and energy consumption.

Safety Protocols: Rigorous safety measures are mandatory due to risks of catastrophic failure at high speeds and temperatures.

Capabilities

Experimental and theoretical studies of gas turbines to map performance curves and internal flow fields.

Analysis, design, and optimization of individual components (compressor, combustor, turbine) for overall performance enhancement.

Detailed modeling of components (compressor, combustion chamber, turbine, etc.) with experimental validation.

Empirical determination of component and full-engine behavior across operating envelopes on the test bed.

Sample Completed Projects

Engine performance modeling and validation using experimental test data.

Optimization of centrifugal compressor stages with laboratory verification.

Combined turbine/nozzle redesign studies for improved overall performance and validation.

Aerodynamic redesign of existing axial compressor blade rows.

Applications of Gas Turbine Test Rigs

New Engine Development: Critical for design iteration and final certification.

Education and Research: Hands-on training and academic investigations.

Military Aerospace: Testing and development of engines for fighter aircraft, UAVs, and missiles.

Power Generation: Performance verification and upgrading of industrial gas turbines for power plants.

Relevant International Standards

ISO 2314: Acceptance tests for gas turbines

ASME PTC 22: Performance test code for gas turbines in power plants

References for gas turbine test lab

Table of contents

Gas turbine test lab

What is the primary purpose of a gas turbine test rig?

✅ To evaluate performance, safety, efficiency, and optimization under realistic operating conditions.

Why is precise testing of gas turbines critical?

✅ It enables efficiency gains, fuel savings, enhanced safety, dynamic analysis, and compliance with standards such as ISO and ASME.

What are the main components of a gas turbine test cell?

✅ Data acquisition system, air/fuel supply system, central control unit, and the engine under test.

Which parameters are measured during testing?

✅ Compressor pressure ratio, thermal efficiency, SFC, temperatures (EGT/TIT), and pressures at key stations.

What are the main steps in the test process?

✅ Preparation & calibration → Test execution across operating points → Data collection & analysis → Safety/fault review → Final reporting.

What are the biggest challenges?

✅ Achieving high measurement accuracy, managing high costs, and maintaining strict safety protocols.

What are the laboratory’s core capabilities?

✅ Performance mapping, component optimization, CFD/experimental validation, and full-engine behavior characterization.

Which projects have been completed?

✅ Engine modeling & validation

✅ Centrifugal compressor optimization

✅ Turbine/nozzle Redesign

✅ Axial compressor blade redesign.

In which industries are these test rigs used?

✅ New engine development, academic research, military aviation, and power-generation gas turbines.

What are the key international standards?

✅ ISO 2314 and ASME PTC 22.