Reverse Engineering of Parts Using Advanced Technology

Practical experience

-

Aircraft Safety Hand Pump

-

18 bar Pressure Regulating Valve

-

30 bar Pressure Regulating Valve

-

Servo Valve

Table of contents

Reverse Engineering of Parts Using Advanced Technology

Introduction

Reverse engineering is a process in which the structure, function, and design of a part are precisely analyzed to obtain the necessary information for its reproduction or improvement. This method is particularly important in industries dealing with sensitive and complex components. Our center, utilizing state-of-the-art technologies and a specialized team, provides reverse engineering services with unparalleled quality. We assure our clients that the redesigned parts will exactly meet their requirements.

Importance of Reverse Engineering Parts Using Advanced Technology

Reproduction of obsolete/rare parts

Enables manufacturing of components that are no longer available on the market.

Performance improvement

Identifying design weaknesses and eliminating them.

Cost savings

Significant reduction in research and development expenses.

Enhanced technical knowledge

Better understanding of the advanced technologies used in the original parts.

Stages of Reverse Engineering Parts Using Advanced Technology

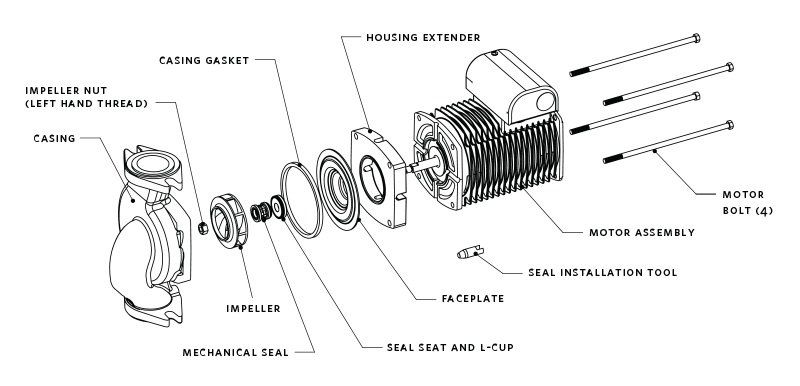

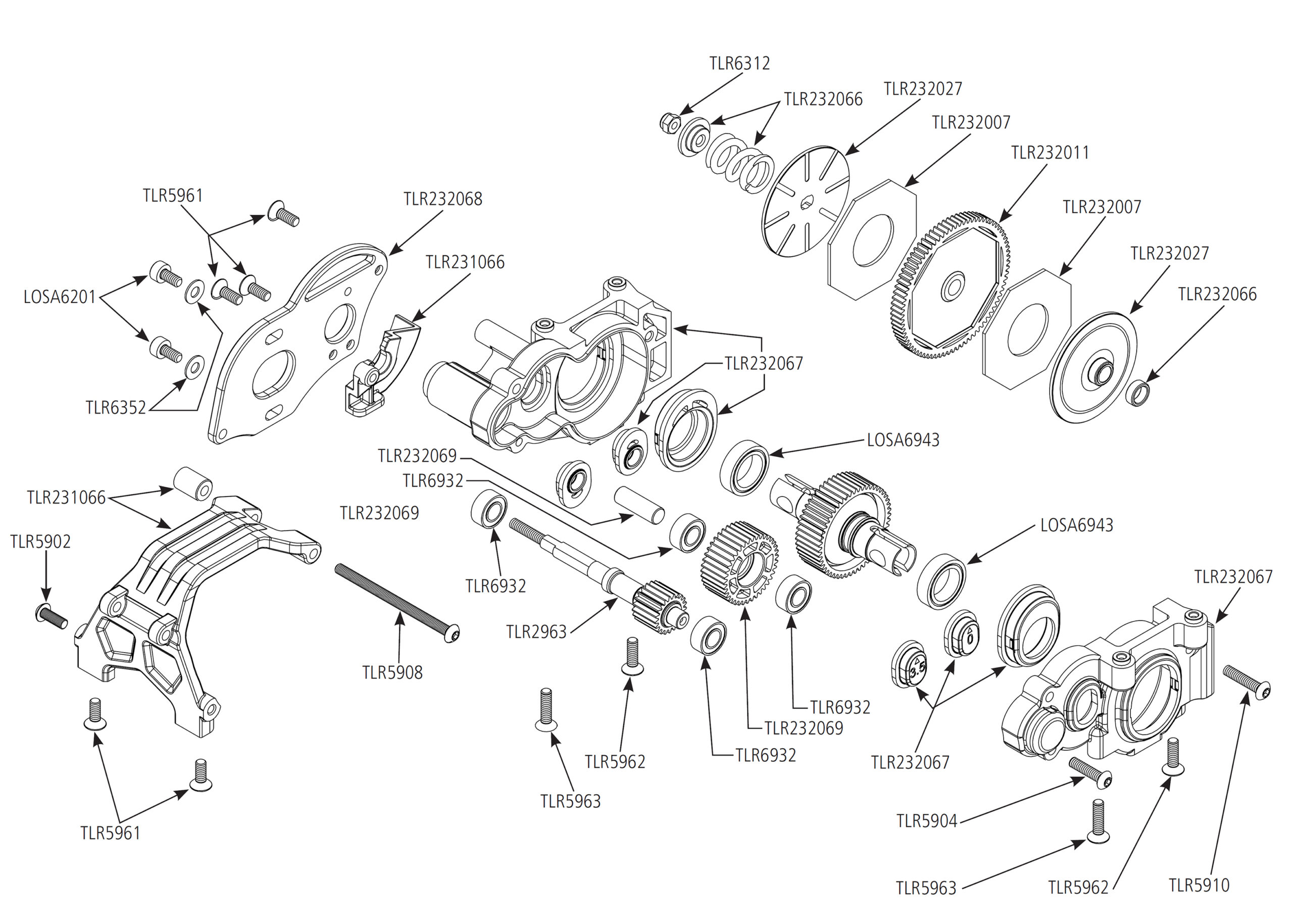

Part disassembly (Demounting)

Components are carefully separated to identify all structural details and materials used.

The disassembly process is accompanied by precise documentation to gather complete information about the part.

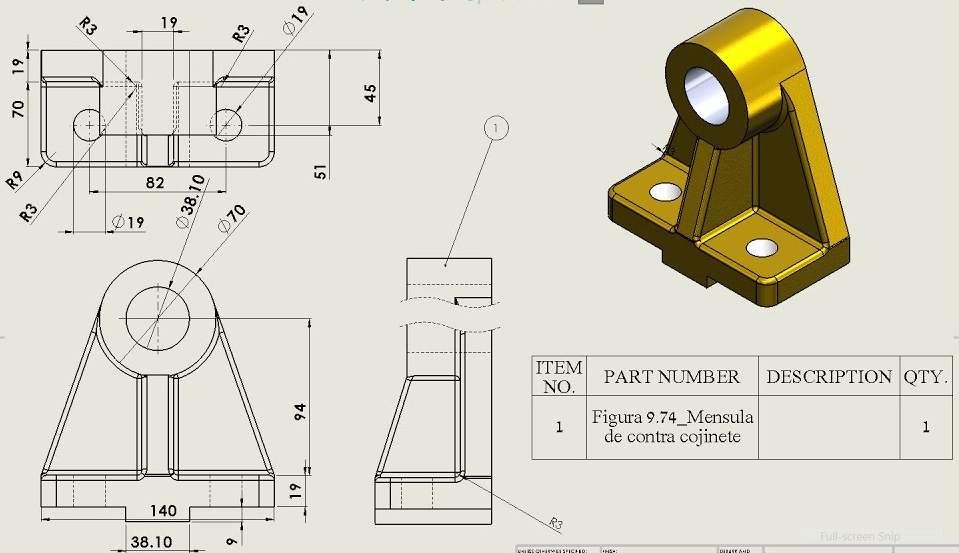

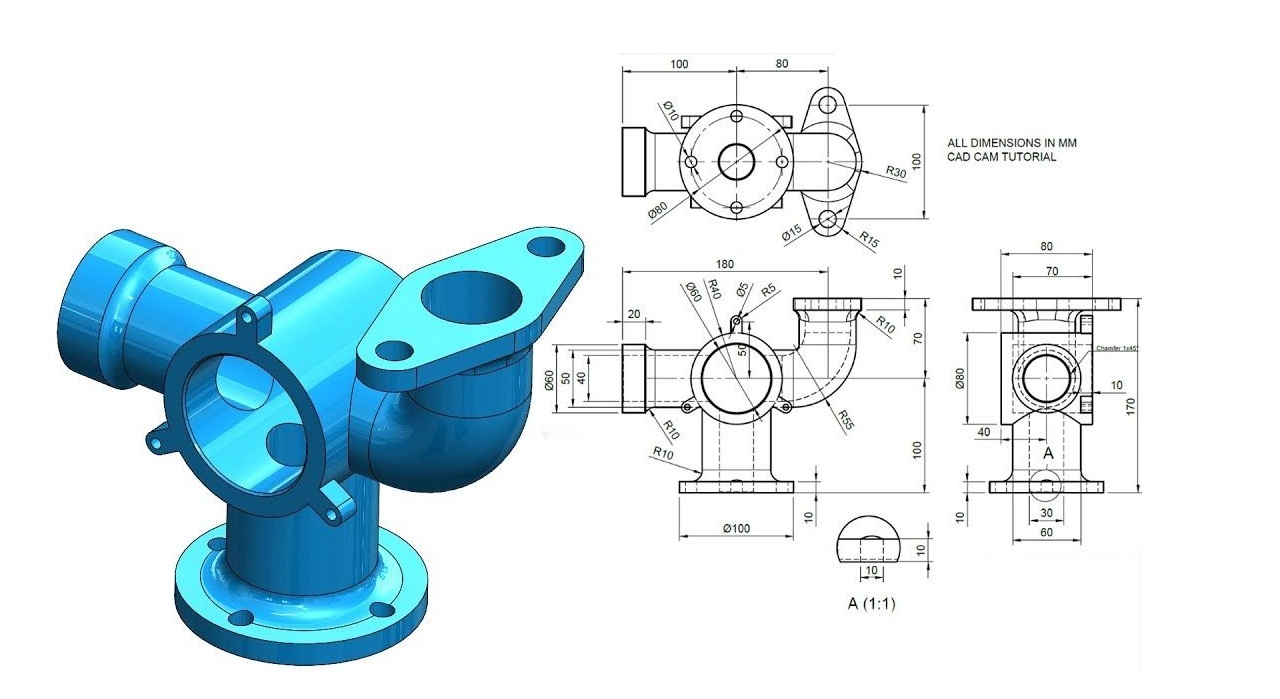

Precise measurement

Use of advanced tools such as 3D scanners, micrometers, and calipers.

Preparation of technical drawings including dimensions and tolerances.

Material analysis

Identification of material composition and mechanical properties.

Performing tests such as spectroscopy and metallography.

2D and 3D modeling

Most of our modeling is 2D and includes simple analyses sufficient for part redesign.

In special cases, 3D modeling is also used for more detailed examination and accurate simulations.

Prototype manufacturing

Building a prototype based on the collected data.

Conducting performance tests to ensure quality.

Troubleshooting and optimization

Identifying potential issues in design or materials.

Providing technical solutions to improve part performance.

Sourcing parts in the market

Our team professionally and on-site searches the market for required parts for reconstruction or replacement.

This process ensures the selection of the best and most cost-effective components for the project.

Advanced Technologies in Reverse Engineering and Design

We use the latest technologies in the reverse engineering process to maximize accuracy and speed. Some of these technologies include:

Advanced 3D scanning: Creates highly accurate digital models of parts, enabling advanced analysis.

Professional 3D printing: Produces high-precision prototypes, allowing us to test new designs faster.

Engineering analysis software: Simulates part behavior under various conditions.

Applications of Reverse Engineering Parts Using Advanced Technology

Reverse engineering is critical in industries requiring precise design, optimization, and reproduction of components.

Valves and pumps: Redesigning and optimizing valves and pumps to improve performance and extend service life.

Turbomachinery Reproduction and optimization of sensitive components in turbines, compressors, and other rotating equipment.

Fluid transfer systems: Analysis and redesign of components to increase efficiency and reduce energy losses.

References on Reverse Engineering of Parts Using Advanced Technology

Table of contents

Reverse Engineering of Parts Using Advanced Technology

What is reverse engineering?

✅ A process in which the structure, function, and design of a part are thoroughly examined to obtain the information needed for its reproduction or improvement.

What are the applications of reverse engineering?

✅ Used for reproducing obsolete parts, improving performance, saving on R&D costs, and increasing technical knowledge.

What is the first stage of reverse engineering?

✅ Disassembly of the part and precise documentation of all structural details and materials used.

How are part dimensions measured in reverse engineering?

✅ Using advanced tools such as 3D scanners, micrometers, and calipers, along with preparing accurate technical drawings.

What tests are performed for material analysis?

✅ Tests such as spectroscopy and metallography to identify material type and mechanical properties.

How is modeling performed in reverse engineering?

✅ Primarily in 2D for redesign purposes, but 3D modeling is also used in special cases for more accurate simulations.

How is prototype production carried out?

✅ A prototype is built based on data from previous stages and undergoes performance testing for quality control.

What technologies are used in the reverse engineering process?

✅ Advanced 3D scanning, professional 3D printing, and engineering analysis software.

In which industries is reverse engineering applied?

✅ Widely used in industries involving valves and pumps, turbomachinery, and fluid transfer systems.

How is troubleshooting performed in reverse engineering?

✅ By identifying potential issues in the design or materials and providing technical solutions to improve the performance of the part.