Fixed equipment design

Practical experience

-

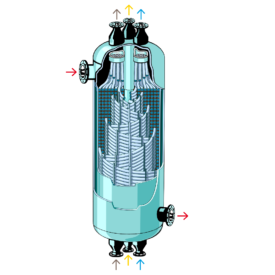

طراحی مبدل حرارتی مارپیچ

Spiral Heat Exchanger

-

طراحی اجیتیتور

Agitator

-

PIG طراحی

(pipeline inspection gauge)

PIG

-

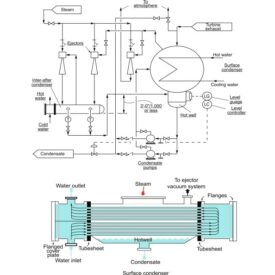

طراحی کندانسور

Condenser Design

Table of contents

Fixed Equipment Design | Principles, Concepts, and Specialized Engineering Services

Introduction

Fixed equipment includes a broad range of industrial devices that, despite having no moving parts, play a vital role in processes involving production, storage, transfer, heat exchange, and material separation. These pieces of equipment are considered the core of process operations in oil, gas, petrochemical, refinery, power plant, pharmaceutical, food, water, wastewater, and many other related industries.

Types of Fixed Equipment

1. Pressure Vessels

Pressure vessels are designed to hold fluids at pressures higher than atmospheric pressure. They must withstand internal pressure, temperature, external loads, and corrosion. Selecting the head type, shell thickness, material, and nozzle design are key stages in their design. ASME Section VIII is the primary standard for their calculations.

2. Storage Tanks

Storage tanks are used to store large volumes of liquids and gases at pressures close to atmospheric. These tanks may have fixed roofs, floating roofs, or double walls. Their design must consider corrosion resistance, structural stability, wind load, seismic load, and environmental conditions. Design follows API 650 and API 620.

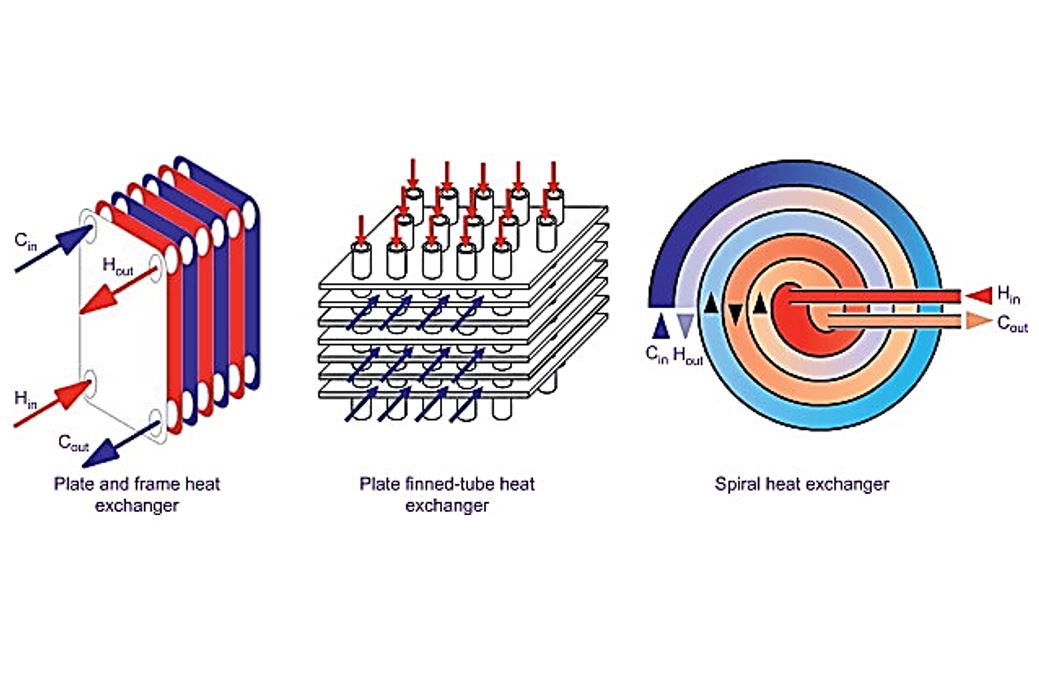

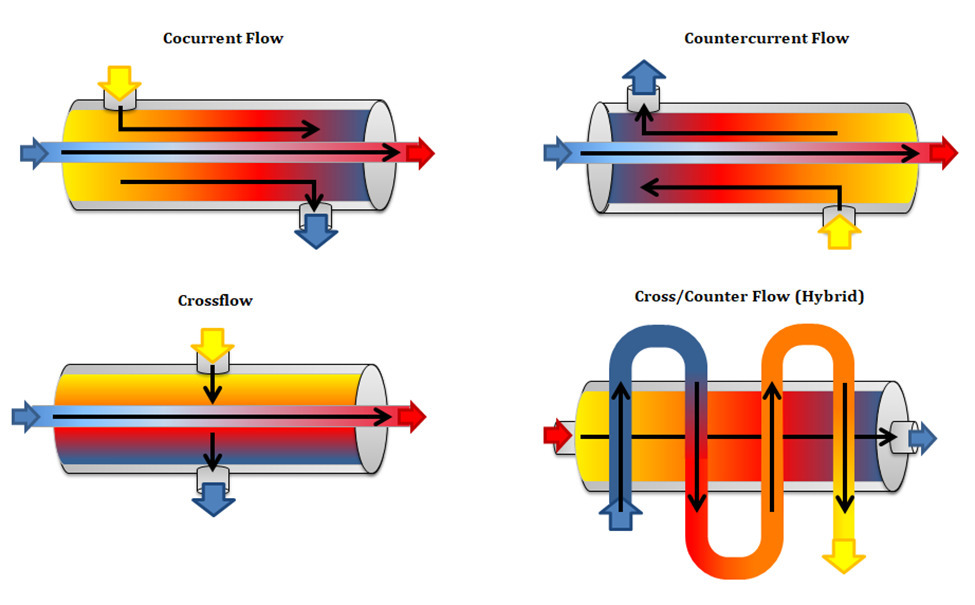

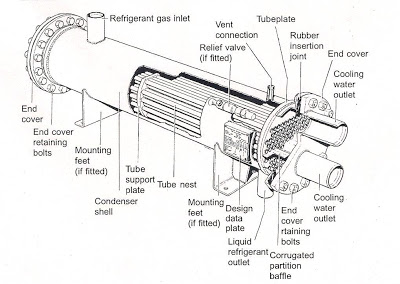

3. Heat Exchangers

Heat exchangers transfer heat between two or more fluids. They are essential in refineries, power plants, and chemical industries. Their design includes thermal analysis (heat duty), pressure drop evaluation, and selection of tubes, baffles, shell type, and mechanical calculations. Adhering to TEMA is essential to prevent vibration, fouling, and to maximize energy efficiency.

4. Boilers and Drums

Boilers generate steam at various temperatures and pressures. Their design must consider internal pressure, thermal shocks, fouling, and stresses caused by temperature fluctuations. Drums are used for vapor–liquid separation and require precise calculations for volume, pressure, and flow distribution.

5. Separators and Filters

Scrubbers are used to remove contaminants, dust, acids, and particles from gas streams. Their design includes selecting the mist eliminator or contact layers, choosing the scrubbing fluid, evaluating pressure drop, and analyzing the chemical composition of the inlet stream. Proper scrubber performance significantly reduces pollution and protects downstream equipment.

6. Scrubbers and Gas Washers

These devices are designed for phase separation such as gas–liquid, liquid–liquid, or solid–fluid separation. Separation quality depends on internal geometry, baffles, plates, and filter type. The design must match the fluid characteristics, flow rate, pressure, and temperature.

7. Piping and Industrial Piping Systems

Piping serves as the fluid transfer network in an industrial unit. Its design includes selecting pipe size, material type, thickness based on pressure and corrosion, stress analysis, support design, and thermal expansion control. Piping design must comply with ASME B31.3.

Key Concepts in Fixed Equipment Design

1. Process Design

This stage determines operating pressure, design pressure, minimum and maximum temperatures, fluid type, physical and chemical properties, and flow rate. Process data form the basis of all mechanical and structural calculations. Even a small error can lead to incorrect equipment design.

2. Thickness and Stress Calculations (Mechanical Design)

Shell, heads, flanges, and nozzles are sized based on internal and external pressure, allowable stress of materials, corrosion allowance, and environmental loads. Calculations must comply with standards such as ASME Section VIII, EN 13445, or API to ensure complete safety.

3. Material Selection

Materials must resist corrosion, high temperature, and mechanical stresses. Acidic fluids may require special stainless steels or nickel alloys. Materials must also offer good manufacturability, weldability, and testability.

4. Thermal Design

For equipment such as heat exchangers, boilers, and reactors, thermal design includes determining heat transfer rate, allowable pressure drop, heat transfer area, and fouling considerations. This stage directly affects energy efficiency, fuel consumption, and overall performance.

5. Structural Design and Supports

Supports must withstand operating loads, equipment weight, vibrations, wind load, seismic forces, and thermal stresses. Proper support design prevents deformation and shell failure, ensuring overall system stability.

6. Nozzle Design

Nozzle design involves determining position, size, flange type, reinforcement thickness, and stress evaluation at the connection area. Nozzles must be designed to maximize flow efficiency and minimize stress.

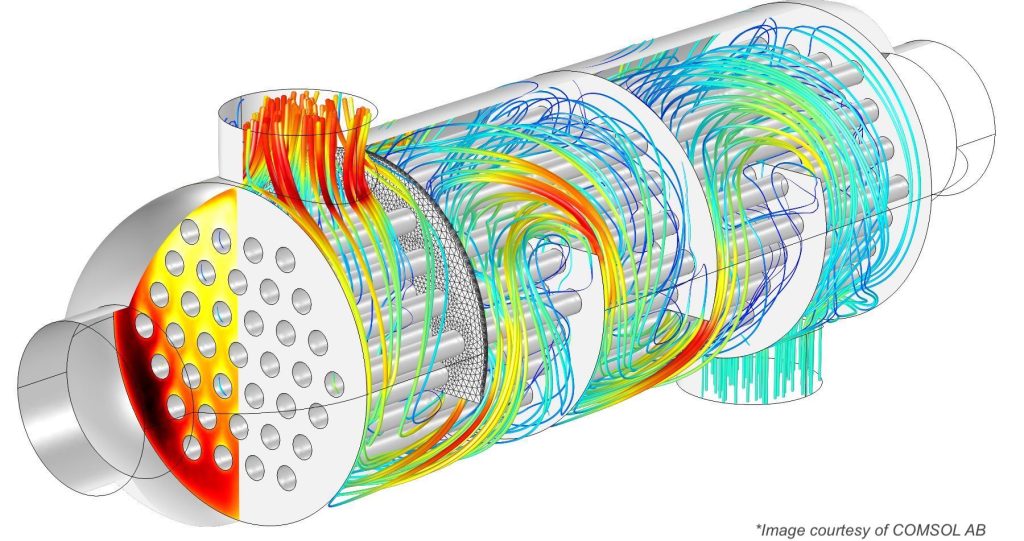

7. Numerical Analysis (FEA/CFD)

For critical equipment, stress analysis using Finite Element Analysis (FEA) and fluid analysis using CFD are performed. These analyses help identify weak points, prevent failures, reduce vibrations, and increase design accuracy.

8. Corrosion Assessment and Equipment Life

For critical equipment, stress analysis using Finite Element Analysis (FEA) and fluid analysis using CFD are performed. These analyses help identify weak points, prevent failures, reduce vibrations, and increase design accuracy.

9. Design for Fabrication Feasibility

The final design must be practical and economical to manufacture. This stage covers weldable thicknesses, welding processes, workshop equipment, inspections, and required tests.

10. Documentation and Drawings

All design results, including construction drawings, calculation manuals, Bill of Materials (BOM), datasheets, and 3D models, are provided to ensure that the manufacturing, installation, and operation processes are carried out without errors.

Some Sources for Fixed Equipment Design

Table of contents

Fixed equipment design

Why is fixed equipment design important?

✅ Fixed equipment design means calculating and selecting materials for equipment that has no mechanical movement but plays a vital role in the process.

What are the most important design standards?

✅ Because these devices are the core of process operations and must safely withstand pressure, temperature, corrosion, and environmental loads.

How is a pressure vessel designed?

✅ ASME Section VIII, EN 13445, API 650/620, TEMA, and ASME B31.3.

What factors are important in material selection?

✅By determining shell/heads thickness, material, nozzles, and reinforcements based on internal/external pressure, allowable stress, corrosion allowance, and ASME VIII rules.

What factors are important in material selection?

✅ Resistance to corrosion, high temperature, mechanical stress, and suitability for fabrication and welding.

How is a heat exchanger designed?

✅ Through thermal analysis (heat duty), acceptable pressure drop, selection of tubes/baffles/shell, and mechanical design following TEMA.

Why is stress analysis essential in fixed equipment?

✅ To ensure safety under pressure, thermal loads, external loads, and to prevent deformation or failure.

What is the function of a scrubber?

✅ To remove contaminants, particles, acids, or pollutants from gas streams.

Why is nozzle design important?

✅Because nozzle size, location, and reinforcement affect flow efficiency and reduce stress concentration at the shell.

What documents are delivered as design output?

✅ Fabrication drawings, calculation book, BOM, datasheets, and 3D models.