Applications of Artificial Intelligence and Deep Learning

Artificial intelligence and deep learning have revolutionized process engineering and mechanical equipment design. At our specialized center, we leverage these advanced technologies to optimize designs, enhance efficiency, and reduce operational costs.

Table of contents

Applications of Artificial Intelligence and Deep Learning

Intelligent Industrial Process Design

Multi-Objective Process Optimization

Utilizing advanced machine learning algorithms such as XGBoost and complex neural networks to comprehensively analyze process data and identify efficiency improvements while considering multiple criteria.

Intelligent Simulation and Process Behavior Prediction

Development of predictive dynamic models based on deep learning (LSTM, Transformers) for accurate simulation of process behavior across a wide range of operating conditions.

Advanced Adaptive Control Systems

Implementation of intelligent control architectures that automatically and in real-time adjust process parameters using reinforcement learning algorithms.

Intelligent Energy Management

Application of data mining and machine learning techniques to optimize energy consumption throughout the entire process chain.

Advanced Design and Optimization of Heat Exchangers

Intelligent Optimal Configuration Selection

Use of multi-objective genetic algorithms and particle swarm optimization (PSO) to identify the most efficient heat exchanger design considering both technical and economic criteria.

Intelligent Fouling Prediction Systems

Development of hybrid predictive models combining deep learning with fundamental physics to accurately forecast fouling onset and recommend optimal cleaning strategies.

Advanced Performance Analysis Platform

Design of deep learning-based fault detection systems capable of early identification of performance issues and providing corrective recommendations.

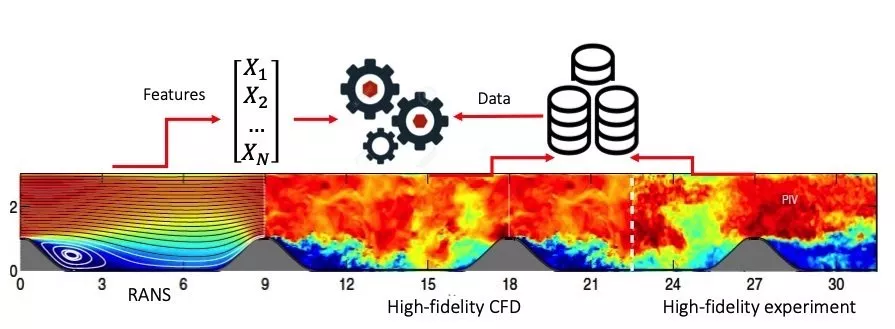

Heat Transfer Optimization

Application of convolutional neural networks (CNNs) to analyze flow and heat patterns and propose innovative designs.

Advanced Digital Design of Turbines and Compressors

Intelligent Aerodynamic Optimization

Implementation of graph neural networks (GNNs) for designing 3D blades with maximum efficiency and minimum energy losses.

Comprehensive Predictive Maintenance Systems

Development of hybrid frameworks analyzing vibration, thermal, and acoustic data using AI and deep learning to accurately predict failures and optimize maintenance scheduling.

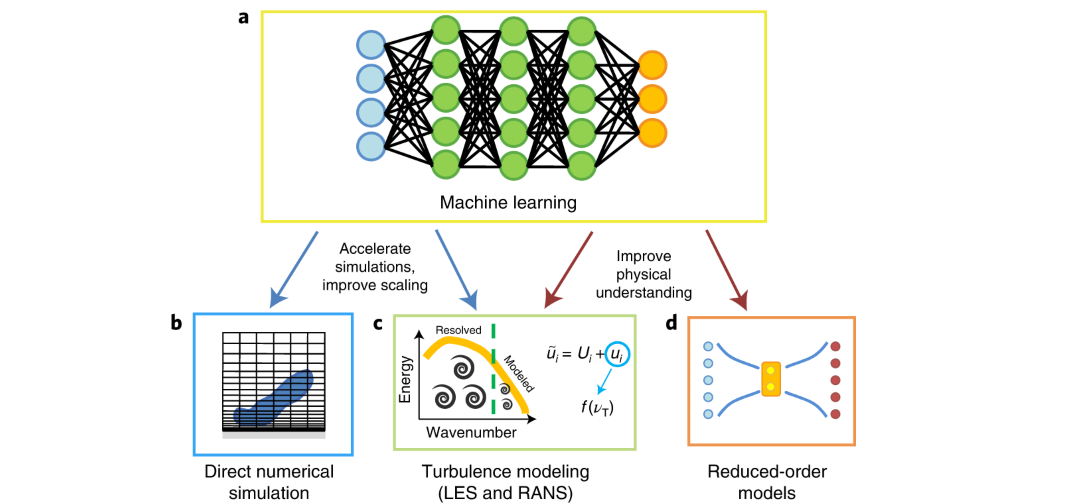

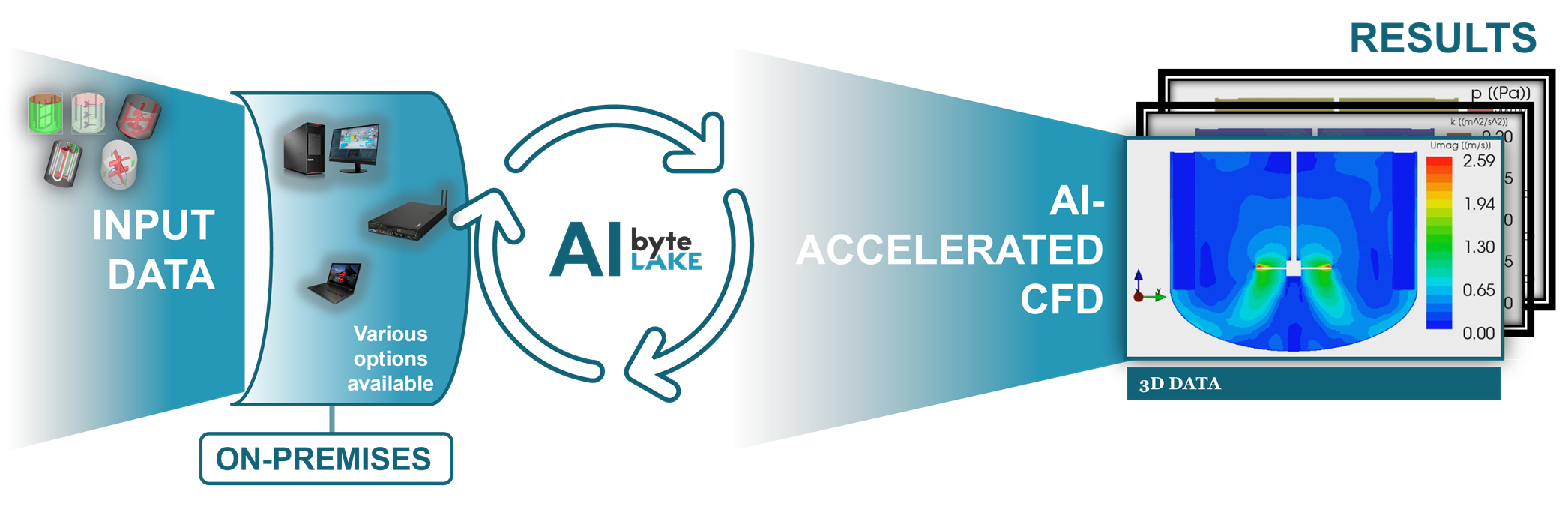

Ultra-Fast Flow Simulation

Integration of traditional CFD methods with machine learning-based reduced-order models (ROM) to perform accurate simulations in a fraction of the usual time.

Duty Cycle Optimization

Use of reinforcement learning algorithms to determine optimal operating strategies under varying load conditions.

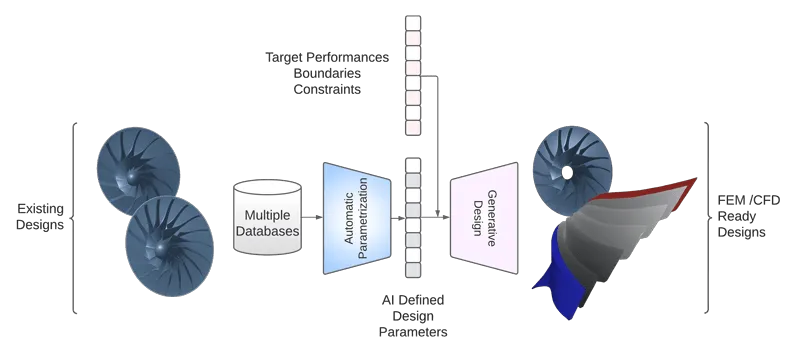

Data-Driven Intelligent Pump Design and Selection

Advanced Pump Recommendation Systems

Development of AI and deep learning-based intelligent platforms that recommend the best pump option considering all process, environmental, and economic parameters.

Hydraulic Optimization with Reinforcement Learning

Application of advanced RL algorithms to explore the design space and identify impeller geometries with maximum efficiency.

Intelligent Energy Management of Pumping Systems

Implementation of adaptive control systems that dynamically match pump performance to network demand.

Condition Monitoring and Fault Detection

Development of unsupervised learning-based anomaly detection models for early identification of performance issues.

Applications of Artificial Intelligence and Deep Learning references

Table of contents

Applications of Artificial Intelligence and Deep Learning

What are the applications of AI and deep learning in industrial process design?

✅ The main goals are to improve efficiency, increase prediction accuracy, reduce costs, and enhance system adaptability to varying operating conditions.

Which algorithms are used for multi-objective process optimization?

✅ Algorithms such as XGBoost, deep neural networks, multi-objective genetic algorithms, and particle swarm optimization (PSO) are employed for process analysis and optimization.

How is deep learning used to simulate process behavior?

✅ LSTM and Transformer models are used to model dynamics and predict process behavior under varying conditions.

How do intelligent adaptive control systems work?

✅ They continuously and in real-time optimize process parameters using reinforcement learning algorithms.

How is intelligent energy management implemented?

✅ By analyzing operational data and forecasting consumption patterns with machine learning to optimize energy use throughout the process chain.

What methods are used for optimal heat exchanger design?

✅ Multi-objective genetic algorithms and particle swarm optimization are applied to select the best configuration based on technical and economic considerations.

How do intelligent fouling prediction systems operate?

✅ By combining deep learning models with physical laws to predict fouling formation time and recommend optimal cleaning strategies.

How are graph neural networks (GNNs) used in turbine and compressor design?

✅ GNNs enable the design of 3D aerodynamic blades that minimize energy losses and maximize efficiency.

What approach is used for predictive maintenance of turbomachinery?

✅ Combining vibration, thermal, and acoustic data with deep learning analysis to predict optimal maintenance timing.

What are the applications of reinforcement learning in pump design and control?

✅ RL is used for hydraulic impeller optimization, adaptive pump performance control, and early detection of operational issues.