Test Definition and Test Circuit Design

Practical experience

-

طراحی مدار آزمون سروو ولو

Servo Valve

-

طراحی مدار آزمون شیر (پنوماتیک) ایزوله هواپیما (فشار 300 بار)

Aircraft isolation valve (pneumatic)

-

طراحی مدار آزمون شیر حساس به ارتفاع (کارکرد در فشار نسبی مثبت و منفی)

Height-sensitive valve

-

طراحی مدار آزمون رگولاتور هواپیما

Aircraft Regulator

-

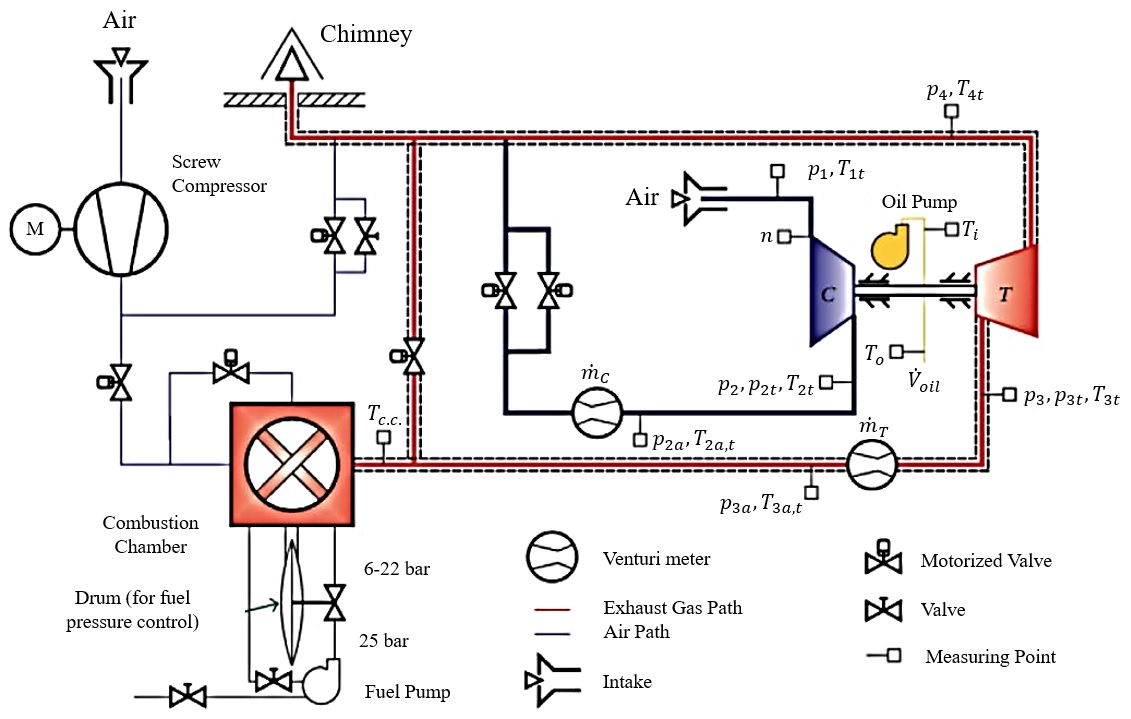

طراحی مدار آزمون پمپهای روغنکاری موتور هواپیما (دما بالا)

Aircraft engine lubrication pumps

-

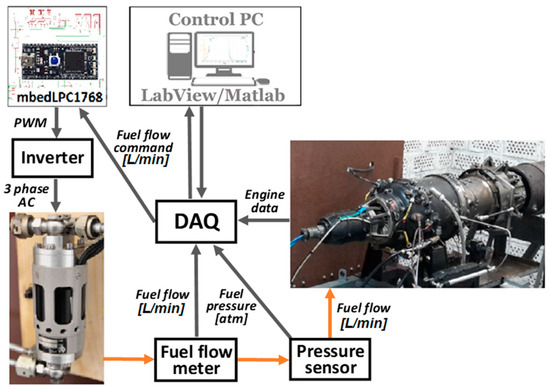

طراحی مدار آزمون پمپ سوخت با قابلیت وارونه کردن پمپ در حین عملکرد

Reversible fuel pump

-

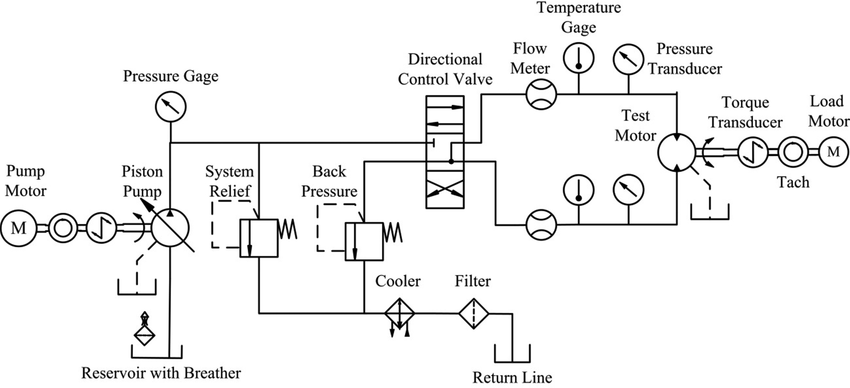

طراحی مدار آزمون دمپینگ اکچویترهای دورانی

Damping of rotary actuators

-

طراحی مدار آزمون نیروی مقاوم اکچویتر دورانی

Rotary actuator resistive force

-

طراحی مدار آزمون مبدل حرارتی سوخت و روغن

Fuel and oil heat exchanger

-

طراحی مدار آزمون مبدل حرارتی روغن (هوا خنک)

Oil heat exchanger (air cooled)

-

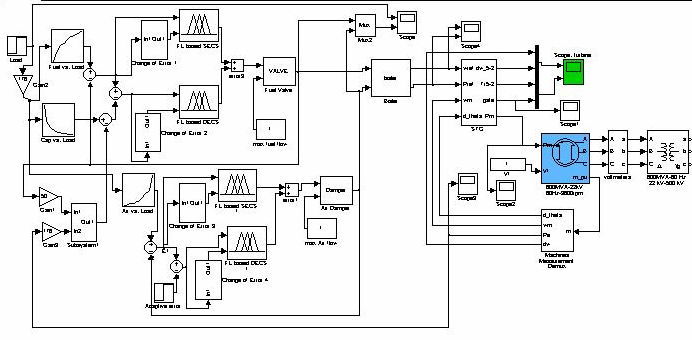

طراحی مدار سوخت پمپ محرک توربینی

Turbine drive pump fuel circuit

Test Definition and Test Circuit Design

Introduction

In the production and development of industrial components, ensuring their correct performance under real-world operating conditions is essential. Designing test circuits (test rigs/test benches) is one of the most important tools for identifying weaknesses, guaranteeing quality, and improving manufacturing processes. These tests help companies deliver higher-quality products with longer service life.

Objectives of Test Definition and Test Circuit Design

Testing and test circuit design pursue various goals that ultimately lead to improved performance and product quality. Some of these objectives include:

Evaluating component performance: Identifying weaknesses and providing solutions to enhance part performance.

Simulating real-world conditions: Assessing component resistance to pressure, temperature, and environmental vibrations.

Extending component lifespan: Predicting and analyzing failure points and proposing optimized designs to increase durability.

Ensuring quality: Confirming that components comply with industry standards and customer requirements.

Stages of Test Definition and Test Circuit Design

Requirements analysis

Identifying the operating conditions under which the component must function (e.g., temperature, pressure, vibrations).

Reviewing relevant standards and setting test parameters accordingly.

Selection of test equipment

Choosing precise sensors to collect performance data.

Using advanced tools such as data logging and analysis software to process the collected information.

Test circuit design

Creating schematic diagrams to show data flow and circuit signals.

Selecting appropriate materials and components for building the test circuit.

Execution of tests

Setting up the circuit and performing initial trials.

Recording data and analyzing results.

Conducting specialized tests

Evaluating circuit performance under simulated conditions to ensure accuracy and reliability.

Performing pressure, temperature, and vibration tests to detect potential weaknesses.

Results analysis and optimization

Comparing results against standards.

Providing recommendations for design improvements.

Troubleshooting and problem resolution

Identifying and analyzing potential issues in the test circuit.

Offering technical solutions for rapid problem resolution and system performance enhancement.

Applications of Test Definition and Test Circuit Design

Test circuit design and reverse engineering play a fundamental role in industries that require high precision and reliability.

These processes are widely used across various sectors, particularly those involving sensitive and complex components:

- Valves and pumps: Testing performance and durability of industrial valves and pumps under varying pressure and temperature conditions.

- Turbomachinery: Evaluating efficiency and safety of turbines and compressors under different operating conditions.

- Hydraulic and pneumatic systems: Examining the performance of these systems in power and fluid transfer.

- Power plant industries and any sector dealing with critical components.

- Turbomachinery: Investigating and optimizing the performance of turbines and compressors using detailed analyses.

سیستمهای هیدرولیک و پنوماتیک: ارزیابی عملکرد این سیستمها برای بهبود انتقال نیرو و سیالات.

References on Test Definition and Test Circuit Design

Table of contents

Test Definition and Test Circuit Design

What is test circuit design?

✅ An engineering process performed to evaluate performance, simulate real-world conditions, and ensure the quality of industrial components so that weaknesses can be identified and eliminated.

What is the main purpose of implementing a test circuit?

✅ To ensure components function correctly under real operating conditions, extend service life, identify failure points, and guarantee the quality of final products.

What stages are involved in test circuit design?

✅ It includes requirements analysis, test equipment selection, circuit design, test execution, specialized testing, results analysis, and troubleshooting.

What is done during the requirements analysis stage?

✅ Operating conditions of the component (temperature, pressure, vibrations) are examined, and relevant standards are determined to accurately configure the test.

What equipment is used in test circuit design?

✅ Precise sensors for data collection, data logging and analysis software, and specialized tools for simulating operating conditions.

How does simulating real conditions help testing?

✅ It enables evaluation of components against pressure, temperature, and environmental vibrations, allowing potential weaknesses and failure modes to be identified.

In which industries are test circuits used?

✅ In valve and pump industries, turbomachinery, hydraulic and pneumatic systems, power generation, and any industry dealing with sensitive components.

How are test circuit results analyzed?

✅ Recorded data is compared with standards, and through detailed analysis, recommendations are provided for design and performance improvements.

What is the troubleshooting process in test circuit design?

✅ Identifying potential problems in the test circuit and providing technical solutions for rapid resolution and system performance improvement.

How does test circuit design affect final product quality?

✅ It increases quality, improves durability, reduces failures, and ensures reliable performance under real-world conditions.